How Filiumenter Ensures Precision and Durability in Every Gear

How Filiumenter.com Ensures Precision and Durability in Every Gear

When it comes to the manufacturing of gears, precision and durability are paramount to ensure optimal performance in mechanical systems. Gears are integral to countless industries, from automotive and aerospace to robotics and industrial machinery. At Filiumenter.com, a leading precision gears supplier in India, the focus is not just on producing gears but ensuring each one meets the highest standards of quality, functionality, and longevity.

Filiumenter’s commitment to precision gears in India is at the heart of its operations. By combining state-of-the-art technology, advanced manufacturing processes, and a keen focus on quality control, Filiumenter has positioned itself as a trusted name in the gear manufacturing industry. Let’s dive into how Filiumenter.com guarantees precision and durability in every gear they produce.

Table of Contents

- Introduction

- Precision Gear Manufacturing: The Filiumenter Approach

- Durability: Built to Last

- Filiumenter’s Focus on Customer Satisfaction

- Industry Applications of Filiumenter Precision Gears

- Conclusion

Precision Gear Manufacturing: The Filiumenter Approach

The primary goal for any durable gears supplier in India is to ensure that the gears produced meet the specific requirements of the machinery they are designed for. Whether it's for high-speed machinery or heavy-duty industrial systems, precision is key.

Filiumenter employs a multi-step process to guarantee the accuracy and precision of its gears:

-

Advanced Design & Engineering: Filiumenter’s design team begins the process by leveraging cutting-edge design software, ensuring that every gear is precisely tailored to meet customer specifications. The design phase focuses on critical parameters such as tooth geometry, gear ratio, and material selection, ensuring that each gear can handle its intended load and stress.

-

High-Quality Raw Materials: Precision gears are only as good as the materials they are made from. Filiumenter uses premium-grade raw materials that undergo rigorous testing for quality and durability. From stainless steel to specialized alloys, each material is selected based on the specific mechanical properties required for maximum efficiency and performance.

-

CNC Machining for Precision: Filiumenter utilizes advanced CNC machining technology to manufacture gears with an unparalleled level of precision. Computer Numerical Control (CNC) machines ensure that every tooth, slot, and shape adheres to exact measurements, minimizing the risk of error and ensuring the highest possible precision in gear production.

-

Quality Control and Testing: Filiumenter understands that even the smallest imperfection can compromise the performance of mechanical gears. That's why their manufacturing process includes thorough quality checks at every stage. Advanced testing equipment, such as gear profile measuring instruments and surface roughness testers, ensures that each gear meets industry standards and customer specifications before it leaves the factory.

Durability: Built to Last

While precision is vital, the durability of gears is equally crucial. Gears are subjected to significant stresses during operation, including high torque, fluctuating speeds, and environmental factors. A durable gear ensures that the machinery it powers remains operational without frequent maintenance or failure. Filiumenter’s mechanical gear quality is a reflection of its commitment to creating gears that are built to last.

Several factors contribute to the exceptional durability of Filiumenter’s gears:

-

Superior Material Selection: Filiumenter prioritizes materials that offer both strength and wear resistance. By choosing high-quality alloys and heat-treated materials, the gears can withstand extreme stress and perform reliably over long periods.

-

Advanced Heat Treatment: Heat treatment plays a pivotal role in enhancing the strength and toughness of gears. Filiumenter’s gears undergo precision heat treatment processes like carburizing and tempering, which improve the hardness of the gear teeth, making them resistant to wear, pitting, and fatigue.

-

Surface Coatings: To further enhance the durability of gears, Filiumenter employs specialized surface coatings such as nickel plating and ceramic coatings. These coatings offer additional protection against corrosion, reduce friction, and improve overall performance, especially in harsh or corrosive environments.

-

Rigorous Testing: Filiumenter’s quality assurance team conducts extensive durability tests, such as fatigue tests and wear resistance tests, to ensure that the gears can withstand real-world operational conditions. These tests are designed to push the gears to their limits, simulating long-term use and verifying their performance.

Filiumenter’s Focus on Customer Satisfaction

Another key element of Filiumenter’s approach is its unwavering commitment to customer satisfaction. As a top durable gears supplier in India, Filiumenter understands the diverse needs of various industries. By offering customized solutions, they can cater to specific requirements and ensure that the gears meet both performance and durability standards. Filiumenter’s customer-first approach means that each client gets tailored advice on the best gear options based on their machinery, industry needs, and operational conditions.

Industry Applications of Filiumenter Precision Gears

Filiumenter’s precision gears are trusted across various sectors that demand high-performance and durable components:

- Automotive Industry: Filiumenter’s gears are used in everything from gearboxes to powertrain systems. Precision and durability are essential for automotive components that must function efficiently under high stress and varying speeds.

- Aerospace and Defense: Gears in aerospace and defense applications are subjected to extreme conditions, including high temperatures and heavy loads. Filiumenter’s mechanical gear quality ensures that its products meet these demanding standards.

- Industrial Machinery: From manufacturing plants to robotics, Filiumenter’s gears are used in a wide range of industrial applications, providing precise power transmission and long-lasting reliability.

- Renewable Energy: Filiumenter’s gears also play a critical role in renewable energy applications, such as wind turbines and solar tracking systems, where durability and performance under fluctuating environmental conditions are essential.

Conclusion

Filiumenter.com has solidified its reputation as a leading precision gears supplier in India by focusing on two critical elements: precision and durability. With advanced manufacturing techniques, superior materials, and a commitment to quality, Filiumenter delivers durable gears that perform optimally even in the most challenging environments. By continuously innovating and adhering to the highest industry standards, Filiumenter ensures that its customers receive mechanical gear quality that they can rely on for the long term.

For industries seeking precision and durability in every gear, Filiumenter precision gears stands as a testament to excellence and reliability. Whether for automotive, aerospace, industrial machinery, or renewable energy sectors, Filiumenter continues to be a trusted name in gear manufacturing.

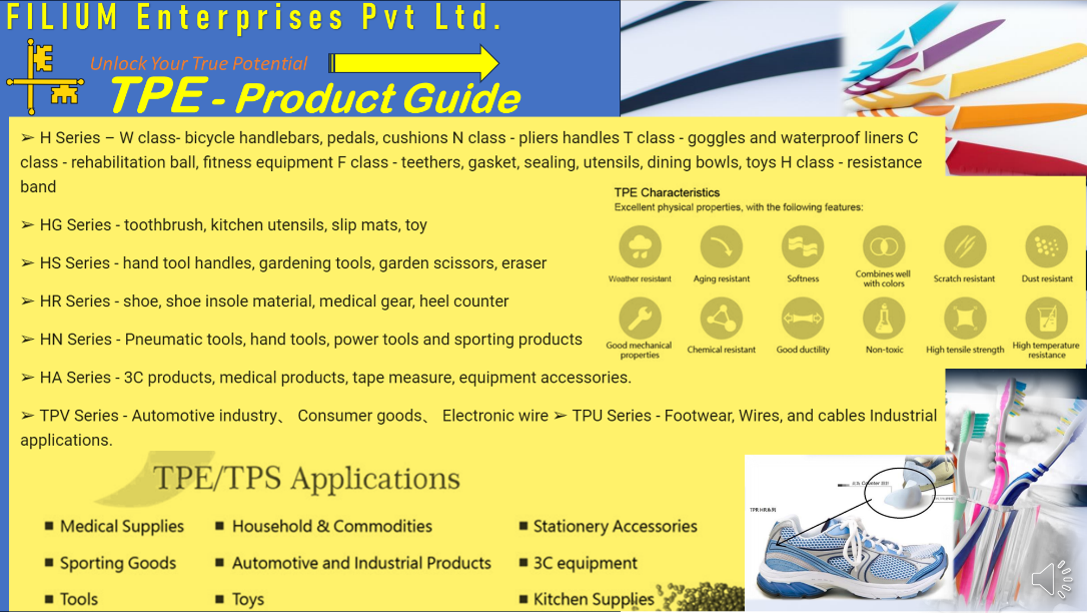

Related Products

Here are some relevant statistics and facts to complement the article on Filiumenter.com and its commitment to precision and durability in gear manufacturing:

Industry Statistics on Gears and Gear Manufacturing:

-

Global Gear Market Size:

The global gear market size was valued at approximately USD 261.3 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2022 to 2030. This growth reflects the increasing demand for precision gears across industries like automotive, aerospace, industrial machinery, and renewable energy. (Source: Grand View Research) -

Automotive Gear Demand:

The automotive industry is one of the largest consumers of gears. It is estimated that the global automotive gear market will reach a value of USD 42.4 billion by 2026, driven by the growing demand for fuel-efficient and performance-oriented vehicles. (Source: Market Research Future) -

CNC Machining Precision:

CNC (Computer Numerical Control) machining offers precision that can achieve tolerances as tight as ±0.002 mm. This level of accuracy is essential for gear manufacturing, ensuring that each gear is made to exact specifications for optimal performance and durability. -

Durability and Wear Resistance:

Studies show that gear teeth undergo significant wear, particularly in high-torque applications. Advanced materials and coatings, such as nickel plating and ceramic coatings, can increase the lifespan of gears by up to 50% in certain applications, making them more durable and resistant to wear and corrosion. (Source: Materials Performance Magazine) -

Quality Control in Gear Manufacturing:

80% of gear-related failures in mechanical systems are caused by issues related to poor quality control, such as inaccurate tooth geometry or material defects. By employing rigorous testing and inspection procedures, Filiumenter ensures that its gears meet the highest standards of quality and precision. (Source: Gear Technology Magazine) -

Gear Profile Measuring:

Modern gear profile measuring instruments can measure the accuracy of gear teeth with a resolution of up to 0.0001 mm, ensuring that Filiumenter’s precision gears meet exact customer requirements and industry standards.

Facts about Filiumenter’s Operations:

-

State-of-the-Art Technology:

Filiumenter employs CNC machining and advanced heat treatment techniques to manufacture gears with high precision, ensuring maximum durability and efficiency. These technologies allow for the production of gears with complex geometries and tight tolerances. -

Material Selection:

Filiumenter uses high-quality raw materials, including specialized alloys, to ensure that their gears perform optimally under various operational conditions. The use of stainless steel and other high-strength alloys enhances the gears' resistance to wear and fatigue. -

Industry-Specific Applications:

Filiumenter’s gears are used across a wide range of industries, from automotive and aerospace to industrial machinery and renewable energy. The versatility of their precision gears makes them suitable for high-performance applications that demand both precision and durability.